CAPABILITIES

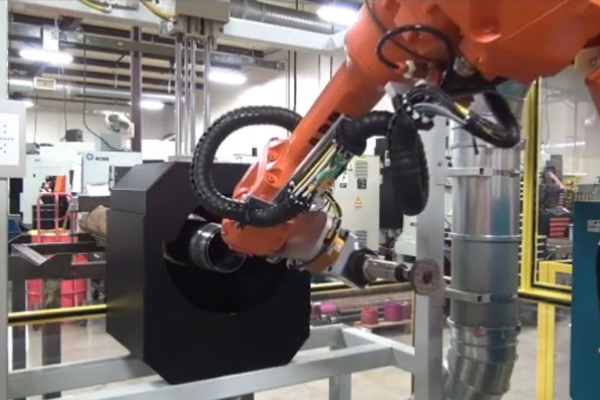

ROBOTICS

The application of automation to the production process has become essential as products and manufacturing processes become more complex. Robotics is the future.

FACTORY AUTOMATION

Today’s manufacturing environment demands quality, repeatability, reliability and efficiency in the production process. ITM has been an industry leader in the deployment of automation and robotics for manufacturing.

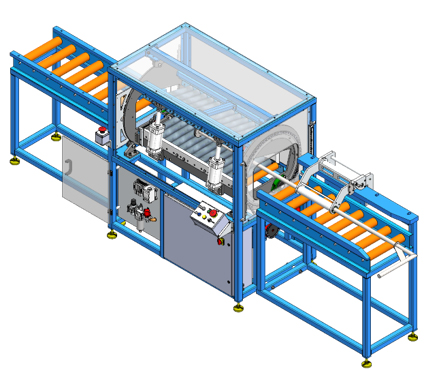

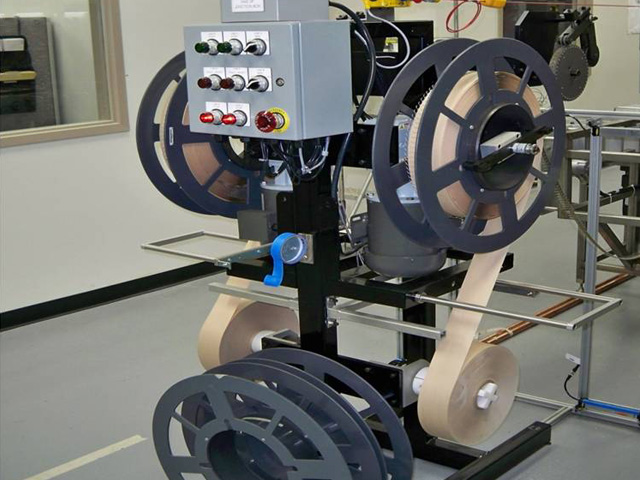

MATERIAL HANDLING

Material Handling is a critical component of today’s manufacturing process. Automated material handling solutions are necessary to take full advantage of the benefits of today’s technology in manufacturing.

VISION INSPECTION

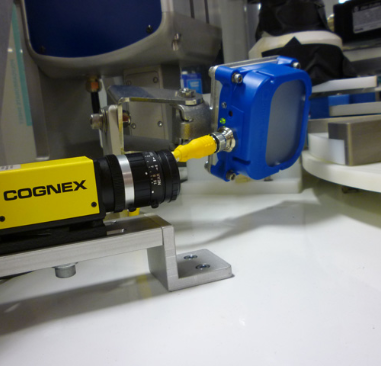

A key element to the advancement of automation and technology within manufacturing is the verification of processes and products during production.

TOOLING

A mainstay of manufacturing, the design and manufacture of prototype and production tooling has been a key component of ITM’s capabilities throughout its 90-year history.

PRECISION MACHINING

ITM has been providing precision machining services to the manufacturing industry since its founding in 1929 and remains a key provider of those services today.

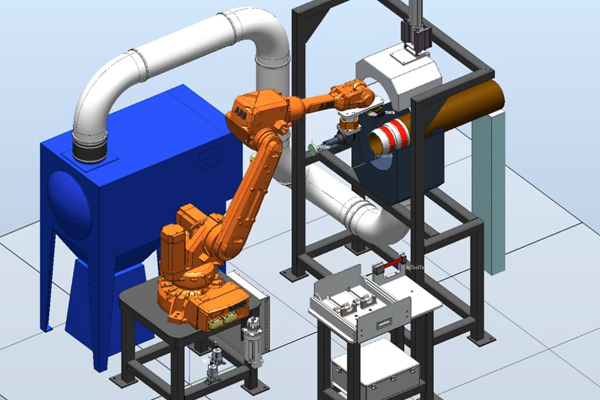

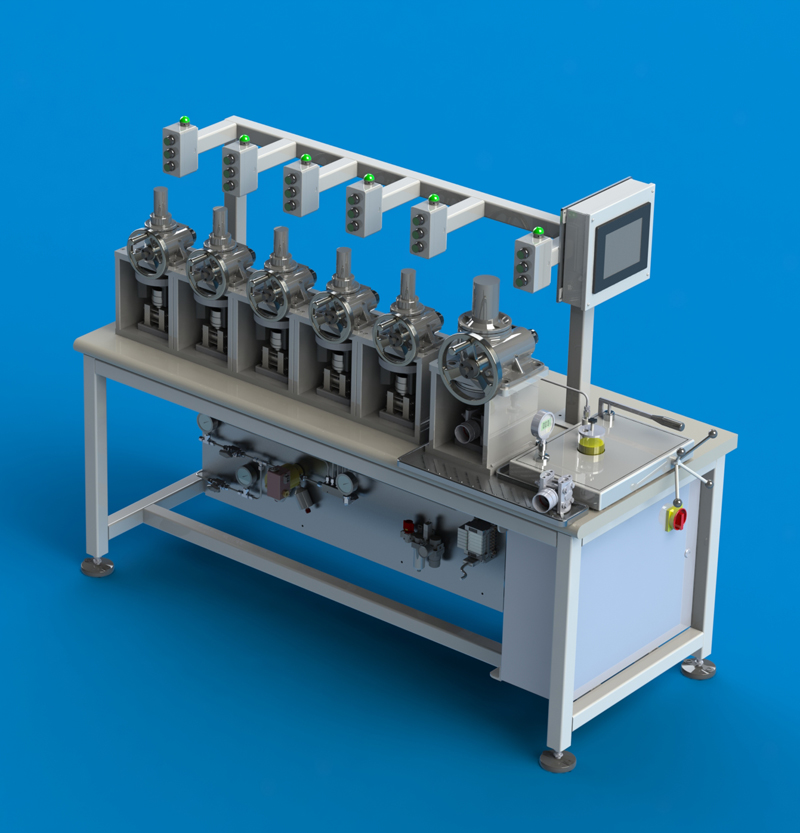

Factory Automation

Ins and Outs of Factory Automation

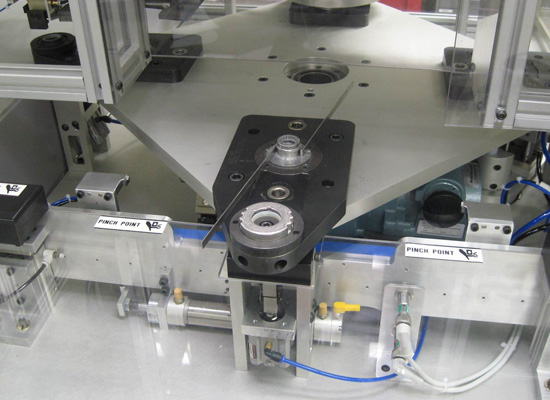

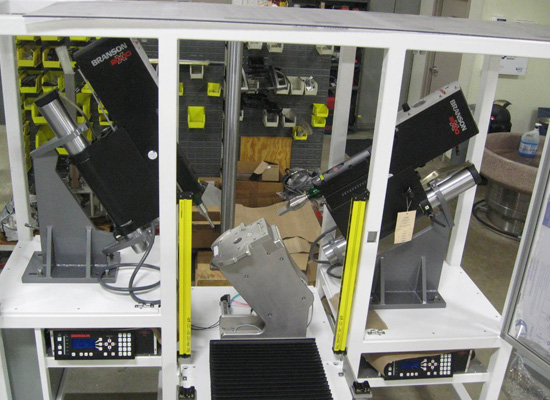

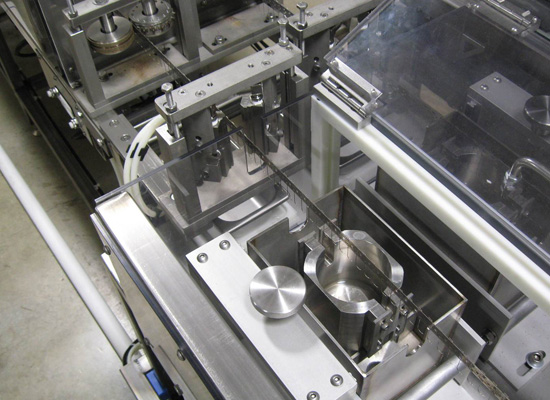

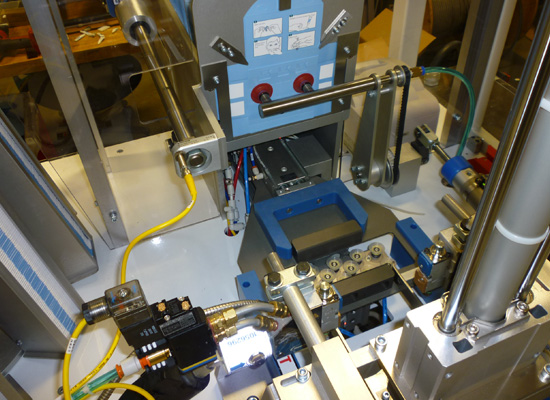

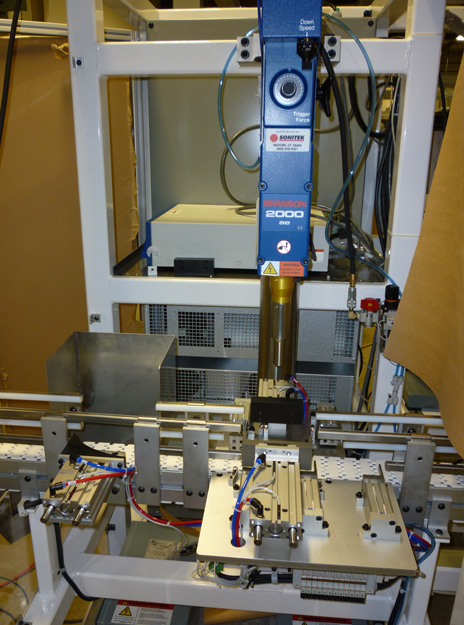

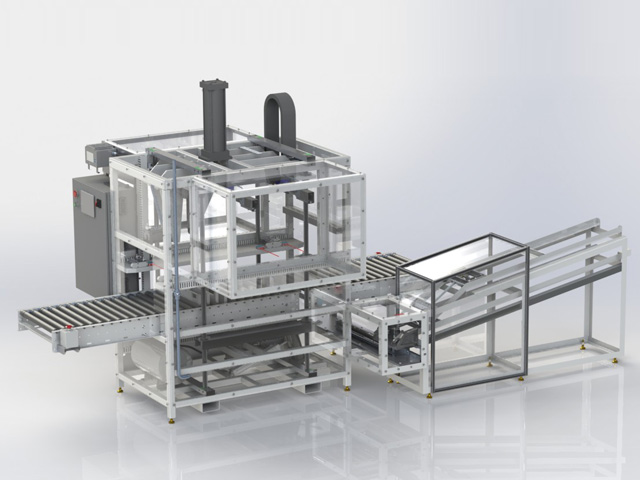

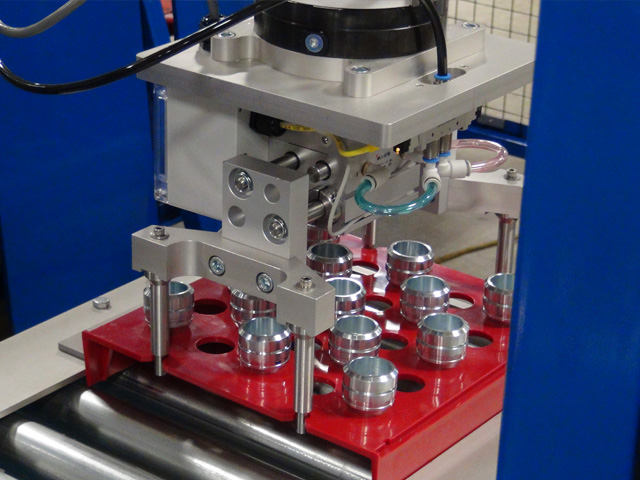

Today’s manufacturing environment demands quality, repeatability, reliability, and efficiency in the production process. ITM has been an industry leader in the deployment of automation and robotics for manufacturing. ITM’s design, manufacturing, and assembly teams provide integrated solutions to meet customers’ production requirements with cost and time-efficient systems. These innovative systems are developed to meet customers’ unique product and production requirements while providing a platform that can be operated and maintained within the customer’s existing resources.

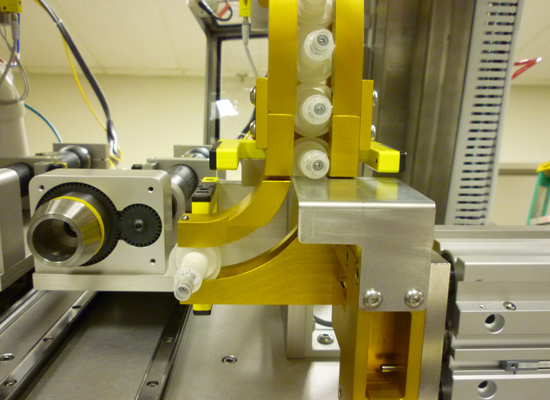

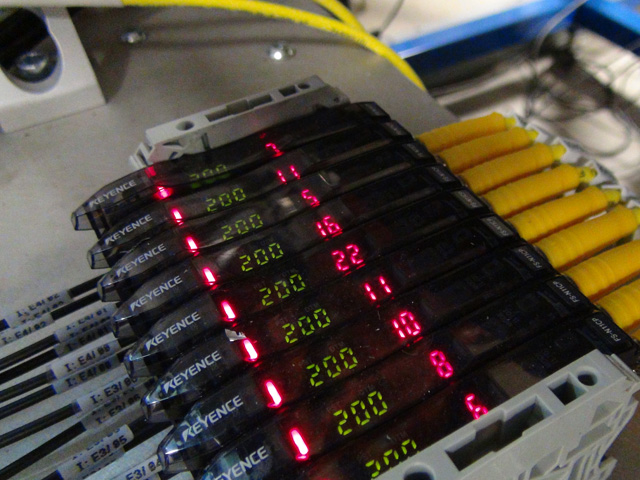

Whether the process solution merely requires a pneumatic-actuated device or a fully automated, “lights-out” production cell, ITM’s team provides a full assessment of the production requirements, the product requirements and the associated manufacturing processes needed to provide a fully integrated solution that will provide a prompt return on the investment. Our innovative solutions have included process control systems, laser & ultrasonic welding applications, dispensing, filling, curing, bonding, marking, assembly, screwdriving, coating/plating, labeling, part orienting/feeding/insertion, inspection, sorting, measurement, pneumatics, hydraulics, robotics, actuation, testing, data recording & collection, and continues to expand.

Industrial automation and controls create scalable, smart machines that enable more efficient and reliable methods of manufacturing. The integration of automated systems into customer’s facilities, plants, and production floors creates optimization of their processes, controls, and operators. This increases quality and flexibility in the manufacturing process with advantages such as increases in productivity, quality, information accuracy, and safety. ITM strives to create, implement, and deliver solutions for our customers that fully encompass the benefits and advances of industrial automated systems.

It All Comes Together

ITM’s in house design and development resources include robotic, mechanical, pneumatic, electrical and control systems development and production. Our customers are provided full-spectrum turn-key concept development, mechanical/electrical/software system design, manufacture, integration, and installation. Services and applications include prototype design and development, 3D solid modeling, automated process control and robotic system design, specialized fixturing, robotic end of arm tooling (EOAT), vision and laser-based inspection, material handling, failure modes and effects analysis (FMEA), PC and PLC-based automated process control systems and equipment design and high and low pressure hydraulic and pneumatic systems design.

Partnerships