CAPABILITIES

ROBOTICS

The application of automation to the production process has become essential as products and manufacturing processes become more complex. Robotics is the future.

FACTORY AUTOMATION

Today’s manufacturing environment demands quality, repeatability, reliability and efficiency in the production process. ITM has been an industry leader in the deployment of automation and robotics for manufacturing.

MATERIAL HANDLING

Material Handling is a critical component of today’s manufacturing process. Automated material handling solutions are necessary to take full advantage of the benefits of today’s technology in manufacturing.

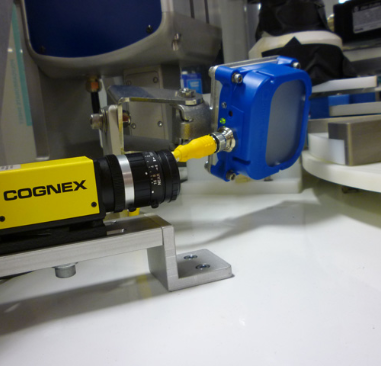

VISION INSPECTION

A key element to the advancement of automation and technology within manufacturing is the verification of processes and products during production.

TOOLING

A mainstay of manufacturing, the design and manufacture of prototype and production tooling has been a key component of ITM’s capabilities throughout its 90-year history.

PRECISION MACHINING

ITM has been providing precision machining services to the manufacturing industry since its founding in 1929 and remains a key provider of those services today.

Material Handling

Automated Movement

Material Handling is a critical component of today’s manufacturing process. Automated material handling solutions are necessary to take full advantage of the benefits of today’s technology in manufacturing and distribution applications. The automated movement, control and management of goods through the manufacturing, packaging and storage processes provides significant cost benefits to the production and distribution of products and eliminate the need for humans to check-in, check-out, sort material or move totes and bins. ITM has been an innovator in the development of intelligent material handling systems to ensure that products are moved, managed, controlled, sorted, picked, positioned, inventoried, palletized, inspected and recorded as necessary to meet the demands of today’s manufacturing facilities.

Our systems are designed to increase productivity while improving efficiency, manufactured with precision and accuracy, then assembled with strict attention to detail. ITM has successfully installed and maintained service and support for over 2,000 systems and machines in a wide array of industries including automotive, aerospace, medical, chemical, food/beverage, etc.

Increase Productivity

ITM’s material handling solutions reduce labor costs and human error while increasing throughput and productivity. By offering innovative and turnkey material handling solutions, our customers are provided with systems dedicated to optimizing storage and order picking operations. ITM always works meticulously alongside our customers to design the solutions that best fits the needs of their company.

Partnerships