CAPABILITIES

ROBOTICS

The application of automation to the production process has become essential as products and manufacturing processes become more complex. Robotics is the future.

FACTORY AUTOMATION

Today’s manufacturing environment demands quality, repeatability, reliability and efficiency in the production process. ITM has been an industry leader in the deployment of automation and robotics for manufacturing.

MATERIAL HANDLING

Material Handling is a critical component of today’s manufacturing process. Automated material handling solutions are necessary to take full advantage of the benefits of today’s technology in manufacturing.

VISION INSPECTION

A key element to the advancement of automation and technology within manufacturing is the verification of processes and products during production.

TOOLING

A mainstay of manufacturing, the design and manufacture of prototype and production tooling has been a key component of ITM’s capabilities throughout its 90-year history.

PRECISION MACHINING

ITM has been providing precision machining services to the manufacturing industry since its founding in 1929 and remains a key provider of those services today.

Vision Inspection

Machine Vision Systems

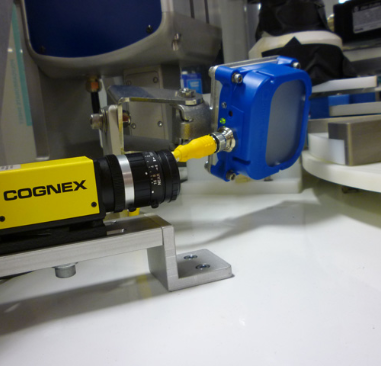

A key element to the advancement of automation and technology within manufacturing is the verification of processes and products during production. Machine vision systems are commonly being utilized as basic feedback sensors across a variety of industrial applications, providing online and offline inspection capabilities. Flexibility in vision software allows for a customized approach to each application. As a provider of turn-key production systems, ITM is able to evaluate the various inspection requirements and determine the proper solution for the specific need, including robot positioning, part alignment, dimensional inspection, equipment/product positioning, fault detection, incomplete/improper parts or assembly, marking, color, labeling, dimensional verification, orientation, defect detection, bar code & human readable marking, process verification, chemical consistency, temperature/force/pressure monitoring, weight, size, profile, etc.

ITM has been instrumental in the development of new inspection techniques to meet the increased demands of today’s automated production requirements. As an approved integrator for the leading manufacturer of vision systems, ITM is also able to draw upon their resources for the evaluation of new technologies to address unique inspection requirements. ITM also possesses onsite vision equipment for performing evaluations and testing for customer applications.

Integration is Key

ITM is experienced in the application of a variety of sensors for monitoring of production processes, including vision, laser (including 3D profiling), thermal, barcode and optical scanning, displacement, scales, etc. as well as the development and integration of the specialized software applications needed to perform these inspections at high speed production rates. In addition, ITM can integrate these inspection requirements into a turn-key production process that includes the management of non-compliant materials and processes in real-time.

Partnerships