What We Do

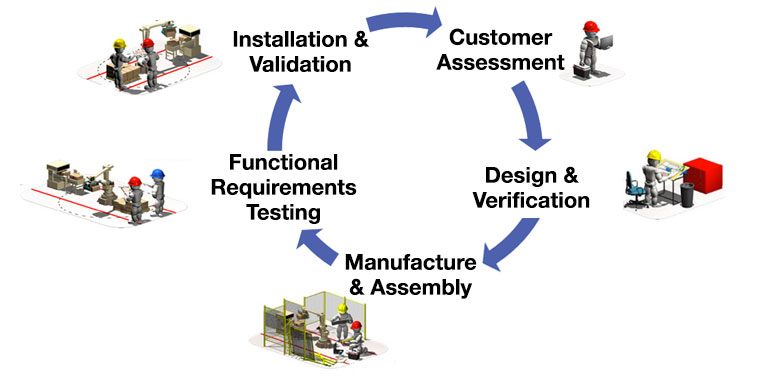

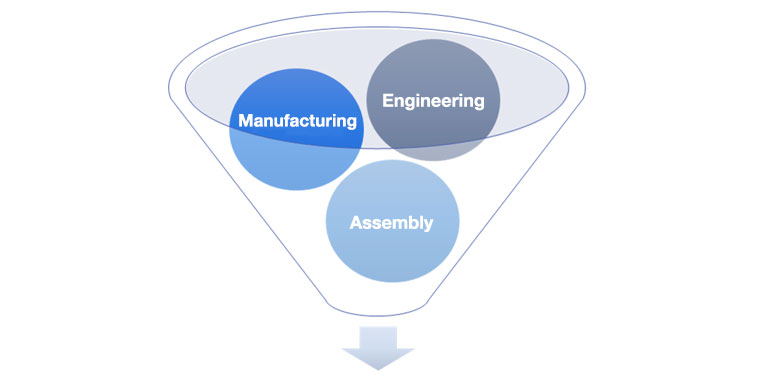

ITM provides a full range of design, development, manufacture, and integration capabilities. Vertically integrated, ITM provides complete turn-key design, manufacture, integration, installation, and training for projects under one roof. A full complement of engineers (mechanical, electrical and controls), machinists, and assembly technicians design, manufacture, assemble and install ITM’s systems, which includes concept development, mechanical/electrical/software system design, manufacture, and integration. This provides full resource and schedule control throughout a project’s duration, allowing for prompt responsiveness to a customer’s changing product and production requirements. ITM’s capabilities also include reverse design analysis of existing systems and equipment for improved performance, supportability, and application to new product requirements.

The Mission

Our mission is to design long-lasting and progressive solutions by harnessing the power of engineering; to build products that not only solve the needs of the customer but provide effective, safe and reliable systems they can trust. Our business values support our vision through technologically, innovation, and creative designs.

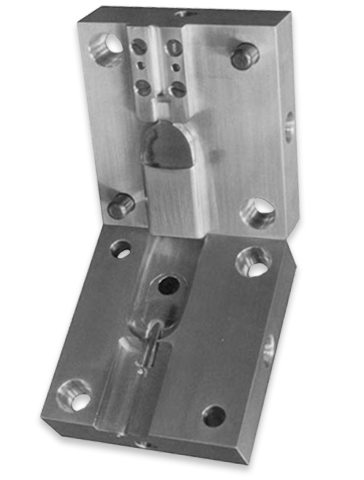

We Do It All

As a turn-key design and production facility, ITM possesses extensive manufacturing capability. To support systems development projects and provide precision machining support for customers, ITM maintains an extensive capital equipment production capability. Our manufacturing equipment includes 14 CNC Multi-axis Machining Centers (Mills and Lathes), including a 5-axis system and over 43 conventional mills, lathes and grinders, a 3-D printer and TIG, MIG, Stick and Gas Welding for the fabrication of tooling, fixtures, molds, and components. Our modern CNC equipment allows for the precise transformation of CAD models into design specified, accurate, and repeatable components. Talented and capable machinists mill and turn parts in a variety of materials, from titanium to tungsten. ITM provides job shop services for part repairs, prototyping, and reverse engineering as part of its full-service machine shop.

International Installs

Our Process

Turn-Key Automated Solutions

Partnerships